UV LED Low Temperature Instant Cure

UV - LED curing systems have a wide range of applications, primarily focused on quickly curing or hardening various materials like inks, adhesives, and coatings. These lamps are used in diverse industries including printing, automotive, electronics, wooden decks, flooring and furniture. They offer benefits like increased production speed, energy efficiency, and reduced environmental impact compared to traditional mercury-based UV lamps. With dramatic savings in time, energy, up front and operating costs UV LED Technology is the future profit maker.

Applications

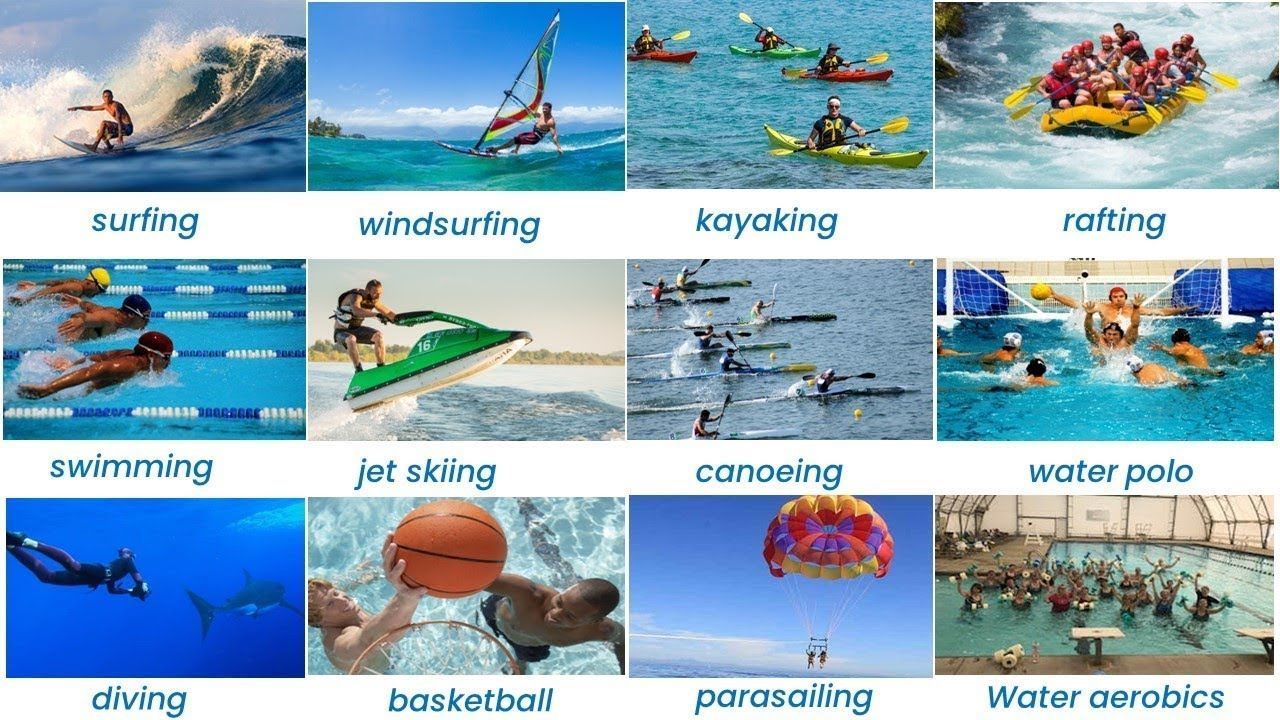

METAL WOOD PLASTIC GLASS ELECTRONICS ADHESIVES

Coatings Adhesive Bonding epoxies & resins General Electronics Inks / Varnishes / Lacquers

Decorative Glazes Laboratories/ R&D Medical Packaging Plastic Products Printed Circuit Boards

Printing/ Label Printing Graphic Arts Resistors / Capacitors Semiconductors leak detection

Easy integration & Application

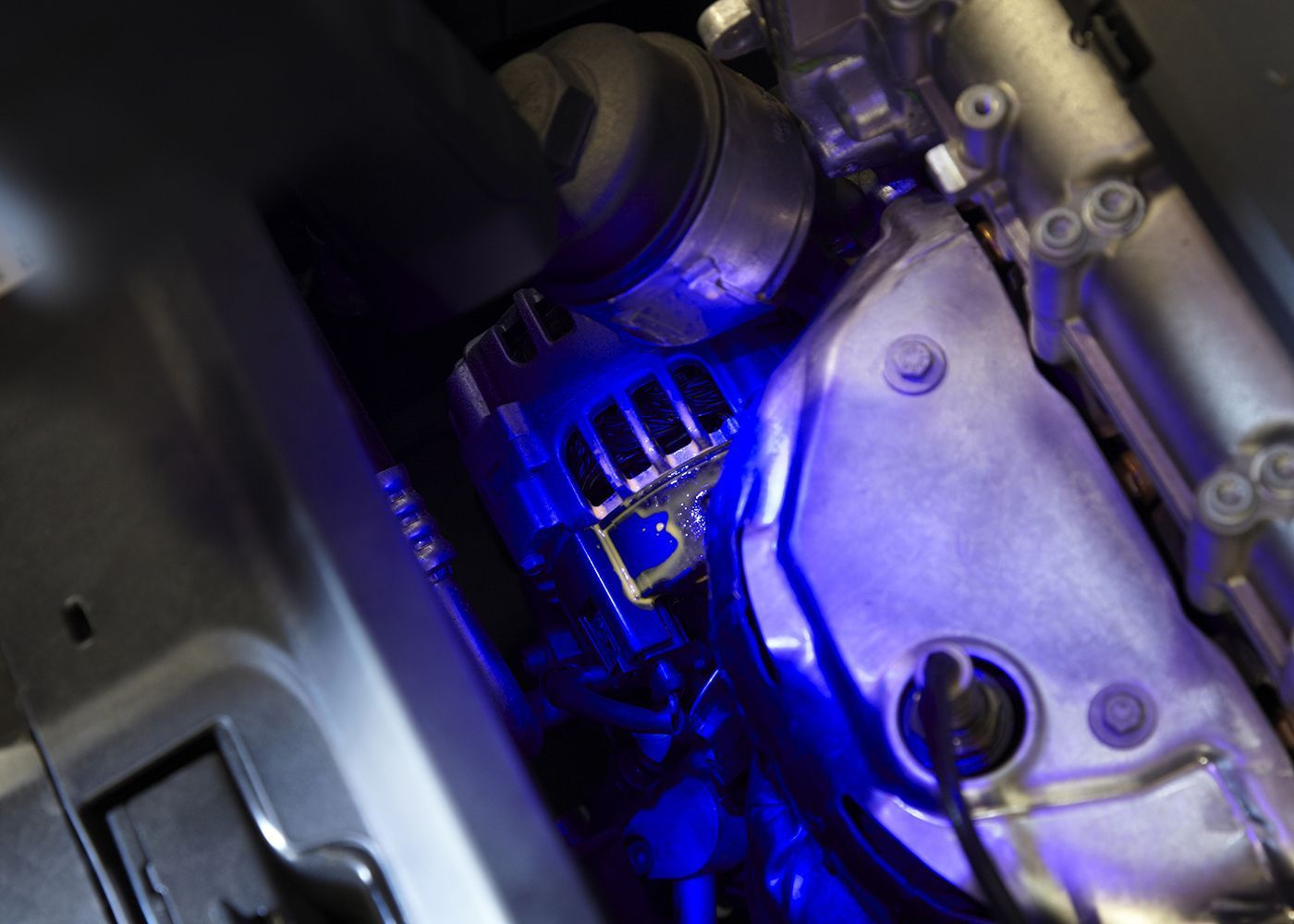

UV-LED curing of resins and epoxies offers rapid, low-temperature solidification and environmental benefits, with applications in electronics for protecting sensitive components, automotive for high-speed production, industrial coatings for durability, and manufacturing for enhanced efficiency. Key advantages include precise curing, improved product quality, reduced energy consumption, and the ability to create solvent-free formulations.

Applications in Various Repair & Maintenance Sectors PDF

Electronics: UV-LED curing is used for encapsulating temperature-sensitive electronic components, protecting them from environmental damage, and providing precise bonding for components that experience mechanical stress.

Industrial Coatings: The durability and protective qualities of UV-cured epoxy resins are utilized in robust flooring solutions and for coating optical fibers to improve their performance.

Manufacturing & Production: The rapid curing process enables high-speed production lines in industries requiring quick turnaround times.

Automotive Industry: UV-cured epoxy resins are valuable for various applications, contributing to enhanced durability and performance.

Wood Finishing: Waterborne UV coatings are used to reduce VOC emissions in the furniture and parquet industries, offering high gloss and excellent scratch and abrasion resistance.

Key Advantages of UV-LED Curing

Speed and Efficiency: The rapid curing process significantly increases production rates and allows for integration into automated manufacturing processes.

Environmental Benefits: UV-LED curing is environmentally friendly, producing minimal volatile organic compound (VOC) emissions.

Low Temperature: The low-temperature curing process is ideal for temperature-sensitive materials and components, reducing thermal stress and potential damage.

Precision: Focused UV light allows for precise curing in specific areas.

Durability: UV-cured epoxy resins offer enhanced durability, strong adhesion, and excellent chemical and moisture resistance.

Energy Efficiency: UV-LEDs consume less energy compared to traditional mercury-vapor bulbs.